|

FireCat Catalytic Combustors User's Guide

Purpose of this Guide

Applied Ceramic's purpose for this guide is that of giving you a better understanding on how the Firecat™ catalytic combustor works in your EPA certified catalytic stove and the role it plays in reducing harmful air pollution. Chief information found in the guide is not a comprehensive document about the operation of any specific catalytic wood burning appliance. We suggest you consult your local fireplace dealer for the specific operating instructions as given by the stove manufacturer. Contents

Origin of the Woodstove Combustor Understanding catalytic’s role in the wood burning stove industry, requires us to look back to the 1970’s when heating costs increased drastically. Oil prices increased 272% in that decade, electric rates increased 215%, while natural gas increased 483%. To combat these cost increases, many homeowners began to switch to wood as a fuel for their heating needs. This was less costly and besides firewood was free and plentiful in many areas. Hundreds of new stove companies began to spring up. Many of them building stoves with efficiency between 50 and 70%. This was as good as or better than gas furnaces and oil burners. However, the advantages of burning wood for heating was also accompanied with some disadvantages.

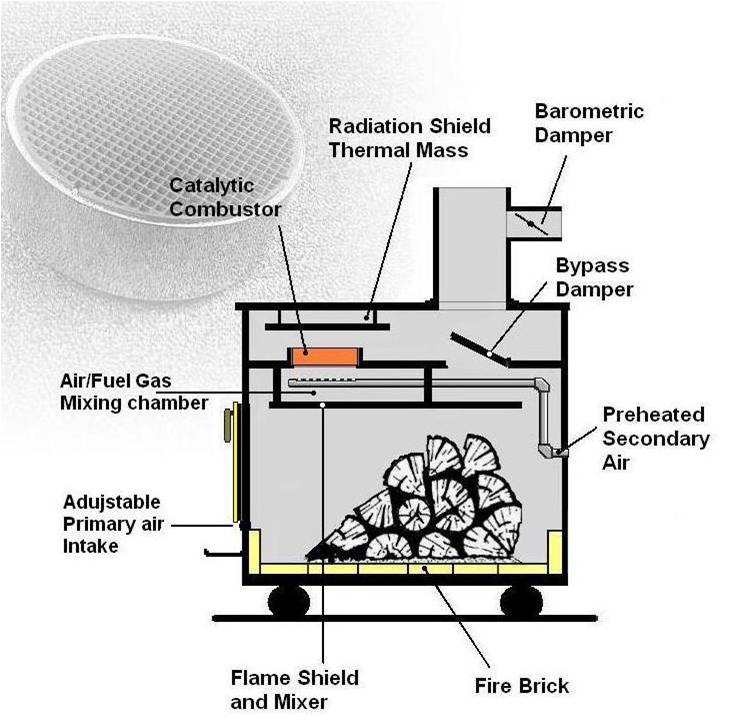

Example Cross-section of a Catalytic Woodstove NOTE: CATALYTIC WOOD STOVES ARE DESIGNED TO BURN NATURAL, SEASONED DRY WOOD ONLY

What is a Catalyst and How Do They Work? By definition, a catalyst is not consumed or used up. The nature of a catalytic reaction is often defined as:

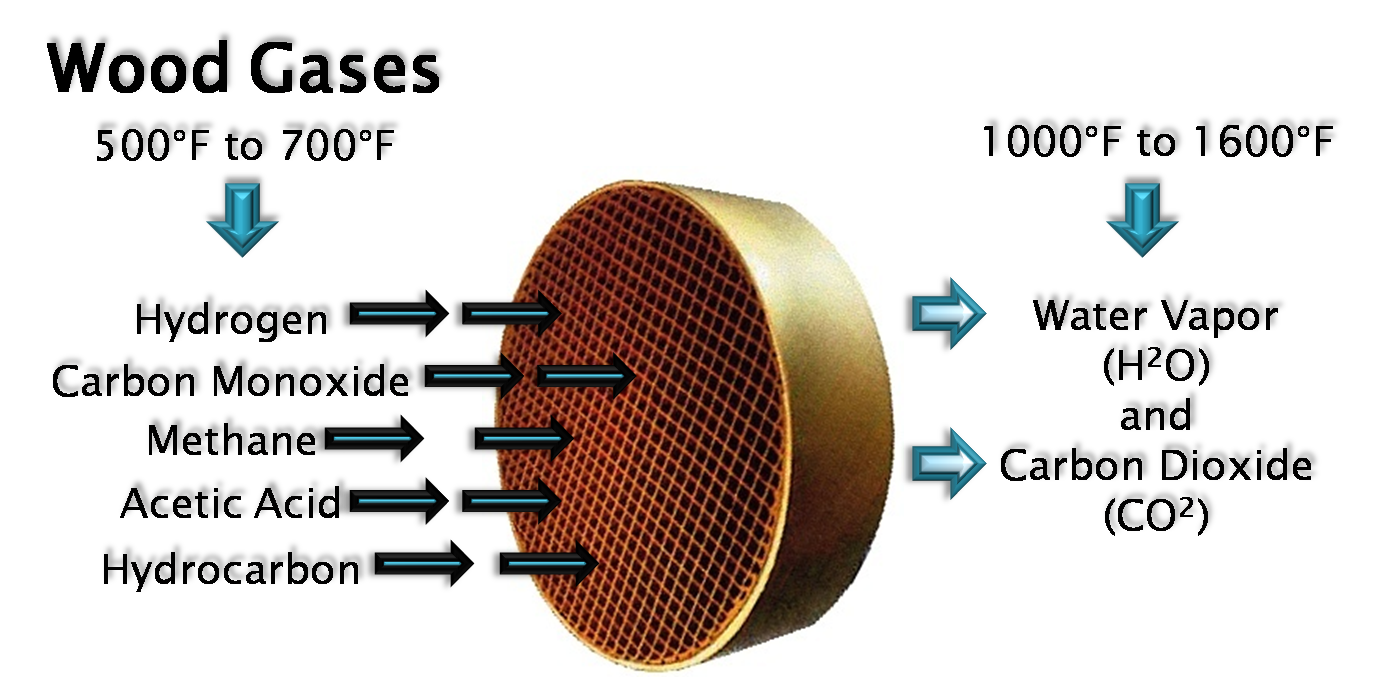

Normally, smoke will burn, or oxidize, at a temperature of 10,000°F or higher. Burning a stove this hot would require continuous intense fire and would require a higher wood consumption. The answer to eliminate this is the catalytic combustor. Wood smoke gases coming in contact with the catalyst causes chemical changes to take place. This will then allow the smoke to ignite at temperatures around 5000°F (or 2600°C). This temperature is easily achieved in the firebox of a wood burning stove. As the gases ignite and burn within the catalytic combustor, clean by-products of water vapor (H20) and carbon dioxide (C0²) are emitted.

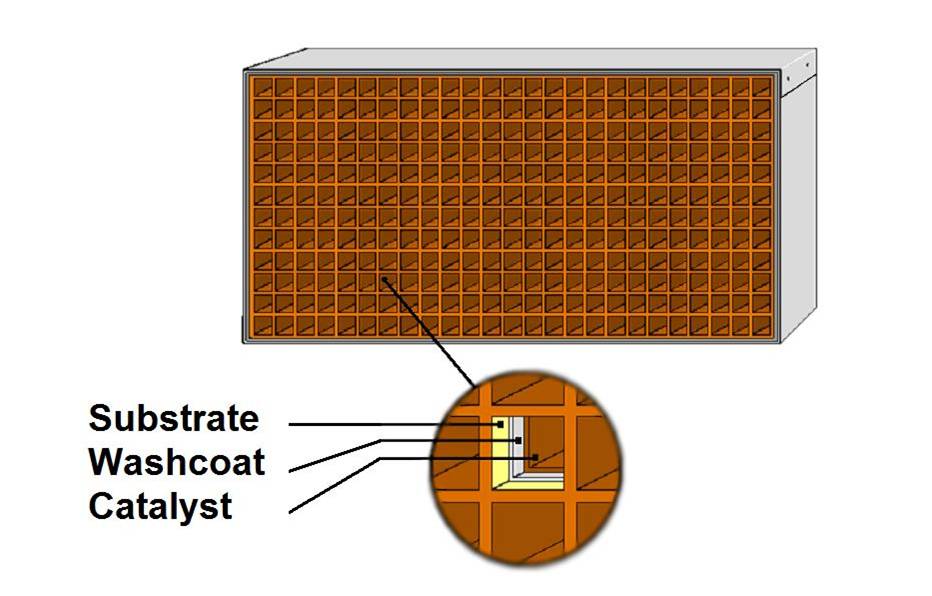

What are Catalytic Combustors Made Of? Most catalytic combustors used in manufacturing catalytic stoves today are made of a high temperature, honeycomb patterned ceramic substrate. They are coated with special noble metals like palladium and/or platinum. The honeycomb pattern gives the combustor surface area for the catalytic coatings.

How To Maintain Catalytic Burning Conditions When Initially starting a cold stove, a medium to high firing rate must be maintained for 20 — 30 minutes. This will allow the stove, the catalytic combustor and the fuel to stabilize at a proper operating temperature, even though the temperature can reach 600°F within a few minutes after the fire has started. After the fire has started, do not turn the fire down to a low burning condition too soon. This can result in the fire and/or the catalytic combustor going out. At the end of the burn cycle, it is possible that the amount of burning charcoal remaining may not provide sufficient temperature or fuel for the catalyst to stay lit. During the refueling of a hot stove that has an internal temperature below 500°F, it is best to fire the stove for 10 — 15 minutes to ensure sufficient temperature and the proper amount of volatile gases for the catalyst to operate efficiently. However, when refueling a hot stove that has an internal temperature above 500°F, no re-firing is necessary. Catalytic Combustor Temperatures Combustor temperatures can become extremely hot during operation. Temperatures above 1600°F will damage the catalyst. Temperatures between 1400°F — 1600°F are normal, but temperatures 1200°F — 1400°F are recommended. Why Combustors Need To Be Replaced

Why Combustors Might Struggle to Work Properly

What To Do When the Combustor Is Not Working Properly

Troubleshooting — Problems, Causes and Solutions

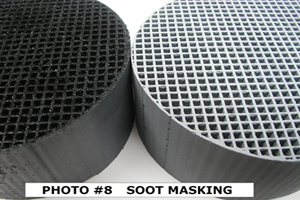

Examples of Combustor Conditions  Click image for close-up Click image for close-upHow To Tell If The Combustor is Working Some stoves are equipped with a combustor view port. It should be noted that the combustor glows during the first 20 — 30% of the burn cycle, when the catalyst is receiving the most smoke and burning at a high temperature. The combustor can reach 1000°F and produce a glow. The combustor does not have to glow to be working. As less smoke is present to burn, the combustor temperature drops and the glow will cease. It is suggested that visual checking NOT be a method of determining combustor functionality. The best method is the use of thermocouplings and following the manufacturer's instructions. This method will read the inlet and exhaust temperatures of the combustor. Another method is to visually observe the exhaust coming from the chimney. When the bypass is in the closed position, and the catalytic combustor is in good operating condition, there should be no dark smoke coming from the chimney. If the catalytic combustor is not working properly, the stove's operator will notice an increase in fuel usage and a build-up of creosote in the system. How And When To Clean The Catalytic Combustor Normally your catalytic combustor requires little or no maintenance as it generates such high temperatures, it basically cleans itself. After the first burning, the combustor should have a light gray powdery appearance. Should the combustor's cells become masked with fly-ash, use a soft bristled brush or paint brush to dust the combustor gently. NEVER USE ANYTHING ABRASIVE to clean the combustor. A vacuum cleaner may be used, but NEVER USE HIGH PRESSURE AIR to blow the cells of any build-up. Any cell blockage can be removed with the use of a pipe cleaner or cotton swab. Should the combustor become masked with soot or creosote, it is possible to burn the accumulation off by opening the bypass and building a hot fire. Once the hot fire is created, close the bypass halfway and burn for 30 — 60 minutes with the bypass in this position. Applied Ceramics strongly recommends that it would be wise to check and clean the combustor before each burning season and inspect all flues for creosote build-up. Cleaning the flue helps prevent chimney flu fires. Helpful Hints on Firewood Hardwoods or Softwoods? Softwoods like Fir, Spruce and Pine are less expensive than hardwoods. Softwoods are easier to ignite and burn rapidly with a hot flame. If you want a quick-warming fire that will burn quickly, softwoods are your best choice. However, if you are a serious wood burner using a catalytic wood burning stove, hardwoods are your best choice. Hardwoods such as Oak and Birch provide a longer lasting fire with a shorter flame. NOTE: Never burn rubbish, chemically treated wood such as discarded railroad ties, utility poles and old yard fences. All will emit poisonous fumes and could add to those materials that collect in the chimney, thus increasing the possibility of a chimney fire. Never burn coal in your catalytic stove. Do not burn artificial or manufactured logs. These are composites of sawdust, chips, colorful chemicals, starch binders and wax. "BURN ONLY SEASONED DRIED WOOD" How To Prepare Your Firewood Splitting and Stacking Splitting logs hastens drying. The key to seasoned wood is that it has been split. Splitting exposes the wet interior and increases the surface area of each piece that is to be air dried or seasoned. Stack split wood or small round logs to allow air circulation and leave it under cover for 10 to 12 months, if possible. This will provide the best heat yield from the wood when ready to use. REMEMBER: Re-fueling with wood that has moisture in or on it will create a damp smoke that shuts the combustor down once the bypass has been closed. Storage It is not necessary to store wood in a garage as a simple covering will suffice. The idea is to keep the moisture off the wood while drying to allow proper ventilation. Store the wood away from the house as it can become a home for insects. Selecting the Right Firewood

How To Buy Firewood The common unit of wood measurement is the standard cord — a pile of wood stacked 8'L x 4'H x 4'W, with a total volume of 128 cubic feet. Because most people don't burn 4 ft. logs, wood is often sold by the "face cord" or rick. This is a woodpile 8'L x 4'H. The depth of the face cord could be 12", 16" or 24". (A 16" depth face is 1/3 of a full cord.) A "truckload" is not a standard measure and depends on the size of the dealer's truck. A standard pickup holds only about 1/3 — 1/2 of a full cord. If you have purchased a cord of wood that you feel is not a full cord or not the species you ordered, contact you State Bureau of Weights and Measures. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||